- 3D Printers and accessoires

- Modeling

- Molding & Casting

- Tin Silicones

- Platinum Silicones

- Dragon Skin™ Series

- Ecoflex™ Series

- Equinox™ Series

- Mold Star™ Series

- Rebound ™ Series

- Smooth-Sil™ Series

- SORTA-Clear™ Series

- Body Double™ Series

- Psycho Paint™

- Platsil Gel & Deadener

- Rubber Glass ™

- Encapso® K

- Solaris™

- Soma Foama™

- EZ-Brush™ Vac Bag Silicone

- EZ-Spray Platinum Silicones

- Silicone Additives

- PU-Rubbers

- Alginate

- PU-Resins

- PU Foam

- Epoxy Resins

- Polyester Resins

- Gypsum & Cement

- Latex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica Latex Rubber

- Monstermakers Foam Latex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's Coating/Dipping Latex

- Holden's Body Latex™ - Brushable

- Holden's Mold Making Latex HX-80™

- Holden's Mold Making Latex High Viscosity HX-974™

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's Cosmetic Latex™

- Holden's Frisket Mask Latex

- Holden's HX-Injection Medium™

- Latex Accessories

- Latex Pigments

- Latex Paint

- Latex Thickener

- AcrylCast

- Prince August

- Concrete Mixtures

- Jesmonite Acryl System

- Buddy Rhodes™ Concrete Products

- Seal and Release

- Additives

- Pigments

- Jesmonite Liquid Pigments

- Pure Pigment Powder

- Ultra Fine Pigment Powder

- Silc Pig™ pigments for silicone

- Glow Worm™ Fluorescent Pigments

- Cryptolyte™ Glow in the Dark

- SilcPig™ Electric fluorescent for silicone

- Siltone Pigments for silicone

- SilTone Kits

- FuseFX Silicone Coloring System

- S.A.M Silicone Coloring System

- Key Pigments for Silicone

- Kryolan Flock Fiber

- Latex Pigments

- Polyester Pigment

- UVO™ - PU-pigments - UV-Resistant

- SO-Strong - PU-pigments

- Ignite™ fluorescent PU-pigments

- Real Metal Powders

- Faux Metal Powders

- Cast Magic™ Powders

- Paints

- Maker Pro Paint™

- Maker Pro Paint™ Fluorescent

- Maker Pro Paint™ Metallics

- Maker Pro Paint Additive

- Vallejo Acrylic Paints

- Vallejo Metal Color

- Vallejo Acrylic Mud

- Vallejo Primers and Laquer

- Psycho Paint™

- MM Latex Paint

- MM Latex Paint Base

- FFX LY-series silicone paints

- FFX F-series silicone paints

- FFX M-series silicone paints

- jesmonite paint

- Fillers and Finishing

- Solvents & Thinners

- Adhesives

- Tools

- Equipment

- Special Make-Up

- Cannom grease paint

- Skin Illustrator palettes

- Skin Illustrator Liquid

- Fleshtone 60ml

- Fleshtone 120ml

- Dark Fleshtone 60ml

- Dark Fleshtone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras 60ml

- Mardi Gras 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Sunburn

- Alphabetical all

- Skin Illustrator Liquid Concentrates

- Fleshtone liquid Concentrate 60ml

- Dark Fleshtone liquid Concentrate 60ml

- FX liquid Concentrate 60ml

- FX liquid Concentrate 120ml

- Alchemy liquid Concentrate 60ml

- Grunge liquid Concentrate 60ml

- Mardi Gras liquid Concentrate 60 ml

- Necromania liquid Concentrate 60ml

- Necromania liquid Concentrate 120ml

- Concentrate Alphabetical

- Skin Illustrator Singles

- Skin Illustrator Glazing Gels

- Skin Illustrator Glazing Spray

- Skin Illustrator Mouth FX

- AlliedFX (Blue Bird)

- RipperFX Palettes

- Stacolor Palettes

- Maqpro Farde Palettes

- Tattoo

- PAX Paints Thomas Suprenant

- MaqPro Make-Up Mixer

- MaqPro Creamy

- MaqPro Bruise Gel

- Old Age Stipple

- Holden's Cosmetic Latex™

- Brushes Make-Up

- Stamps & Molds

- Head Armatures

- Sponges and Applicators

- FormX Tools

- Kryolan Make-Up

- Special effects

- Prostetic Materials

- Help me choose

- Literature

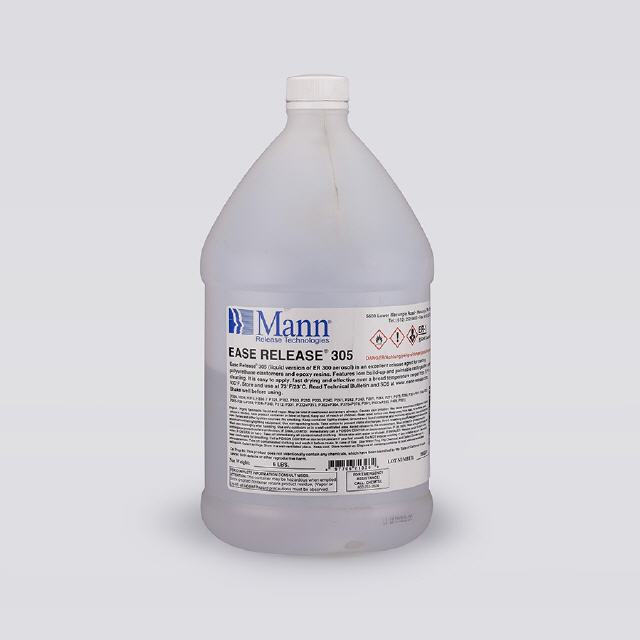

Ease Release™ 305 /2,27kg

Ease Release 305

Ease Release™ 305 is a high performance, production proven release agent formulated for polyurethane elastomers and epoxy resins along with excellent release of polyurethane elastomers and microcellular foams. Ease Release™ 305 leaves very little build-up on the molds resulting from isocyanate or epoxy reactions, while maintaining part cleanability with common degreasing solvents.

Cleaned parts molded with Ease Release™ 305 can be painted or bonded. Ease Release™ 305 is effective on all mold surfaces such as steel, aluminum, chrome, epoxy, and RTV urethane and silicone mold materials.

Features:

Ease Release™ 305 is easy to apply, fast drying and effective over a broad temperature range from 21°C to 260°C.

Ease Release™ 305 provides excellent release with a glossy finish. Precise duplication of mold details, less mold maintenance and down time which results in greater productivity

Application

1 - Thoroughly clean your mold with a suitable cleaner to remove all traces of previous coating and oils.

2 - Apply Ease Release 305 using aerosol spray for bulk grades. Hold the can or spray gun 15 to 20 cm from the mold surface to ensure a light even coating. When the molds are new or have been blasted with an abrasive “season” the mold by applying a heavy coating of release. Heat the mold to process temperature, then wipe the excess with a rag and reapply a light coating of Ease Release 300 before regular molding.

3 - Ease Release 305 is fast drying and requires no baking during the normal molding process.

4 - Reapply a light coating before each molding.

GUIDE

Let us help you find your way.

The list below may help you find what you are looking for via an alternative path.