- 3D Printers and accessoires

- Modeling

- Molding & Casting

- Tin Silicones

- Platinum Silicones

- Dragon Skin™ Series

- Ecoflex™ Series

- Equinox™ Series

- Mold Star™ Series

- Rebound ™ Series

- Smooth-Sil™ Series

- SORTA-Clear™ Series

- Body Double™ Series

- Psycho Paint™

- Platsil Gel & Deadener

- Rubber Glass ™

- Encapso® K

- Solaris™

- Soma Foama™

- EZ-Brush™ Vac Bag Silicone

- EZ-Spray Platinum Silicones

- Silicone Additives

- PU-Rubbers

- Alginate

- PU-Resins

- PU Foam

- Epoxy Resins

- Polyester Resins

- Gypsum & Cement

- Latex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica Latex Rubber

- Monstermakers Foam Latex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's Coating/Dipping Latex

- Holden's Body Latex™ - Brushable

- Holden's Mold Making Latex HX-80™

- Holden's Mold Making Latex High Viscosity HX-974™

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's Cosmetic Latex™

- Holden's Frisket Mask Latex

- Holden's HX-Injection Medium™

- Latex Accessories

- Latex Pigments

- Latex Paint

- Latex Thickener

- AcrylCast

- Prince August

- Concrete Mixtures

- Jesmonite Acryl System

- Buddy Rhodes™ Concrete Products

- Seal and Release

- Additives

- Pigments

- Jesmonite Liquid Pigments

- Pure Pigment Powder

- Ultra Fine Pigment Powder

- Silc Pig™ pigments for silicone

- Glow Worm™ Fluorescent Pigments

- Cryptolyte™ Glow in the Dark

- SilcPig™ Electric fluorescent for silicone

- Siltone Pigments for silicone

- SilTone Kits

- FuseFX Silicone Coloring System

- S.A.M Silicone Coloring System

- Key Pigments for Silicone

- Kryolan Flock Fiber

- Latex Pigments

- Polyester Pigment

- UVO™ - PU-pigments - UV-Resistant

- SO-Strong - PU-pigments

- Ignite™ fluorescent PU-pigments

- Real Metal Powders

- Faux Metal Powders

- Cast Magic™ Powders

- Paints

- Maker Pro Paint™

- Maker Pro Paint™ Fluorescent

- Maker Pro Paint™ Metallics

- Maker Pro Paint Additive

- Vallejo Acrylic Paints

- Vallejo Metal Color

- Vallejo Acrylic Mud

- Vallejo Primers and Laquer

- Psycho Paint™

- MM Latex Paint

- MM Latex Paint Base

- FFX LY-series silicone paints

- FFX F-series silicone paints

- FFX M-series silicone paints

- jesmonite paint

- Fillers and Finishing

- Solvents & Thinners

- Adhesives

- Tools

- Equipment

- Special Make-Up

- Cannom grease paint

- Skin Illustrator palettes

- Skin Illustrator Liquid

- Fleshtone 60ml

- Fleshtone 120ml

- Dark Fleshtone 60ml

- Dark Fleshtone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras 60ml

- Mardi Gras 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Sunburn

- Alphabetical all

- Skin Illustrator Liquid Concentrates

- Fleshtone liquid Concentrate 60ml

- Dark Fleshtone liquid Concentrate 60ml

- FX liquid Concentrate 60ml

- FX liquid Concentrate 120ml

- Alchemy liquid Concentrate 60ml

- Grunge liquid Concentrate 60ml

- Mardi Gras liquid Concentrate 60 ml

- Necromania liquid Concentrate 60ml

- Necromania liquid Concentrate 120ml

- Concentrate Alphabetical

- Skin Illustrator Singles

- Skin Illustrator Glazing Gels

- Skin Illustrator Glazing Spray

- Skin Illustrator Mouth FX

- AlliedFX (Blue Bird)

- RipperFX Palettes

- Stacolor Palettes

- Maqpro Farde Palettes

- Tattoo

- PAX Paints Thomas Suprenant

- MaqPro Make-Up Mixer

- MaqPro Creamy

- MaqPro Bruise Gel

- Old Age Stipple

- Holden's Cosmetic Latex™

- Brushes Make-Up

- Stamps & Molds

- Head Armatures

- Sponges and Applicators

- FormX Tools

- Kryolan Make-Up

- Special effects

- Prostetic Materials

- Help me choose

- Literature

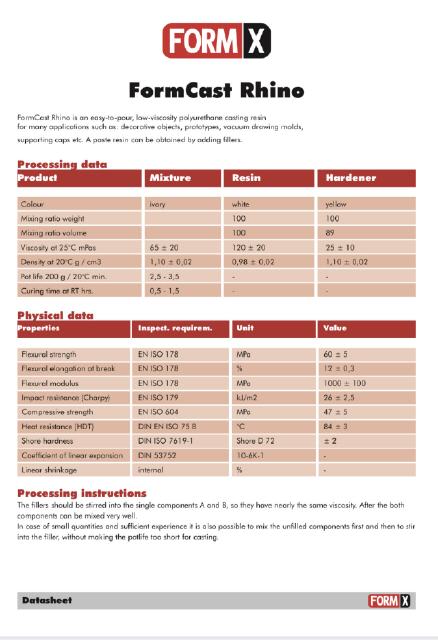

FormCast Rhino

FormCast Rhino

The Form Cast RHINO liquid plastic is an ultra low viscosity resin with ivory color. When properly used it will yield strong, detailed and bubble free castings. Vacuum degassing is not necessary. Form Cast Rhino is suitable for industrial use such as making foundry patterns, core boxes, vacuum forming tools and prototyping. This resin may be mixed with various fillers and dyes. Cured castings are strong and durable and resistant to moisture and mild solvents. They can be sanded, drilled, sawed and - after degreasing - painted. Typical uses include the manufacturing of prototypes, models, sculptures, decorative articles, anatomical models etc .

- verry tough

- high impact resistance

- short demoulding time

- low viscosity

- mixing ratio 100 A - 100 B by weight

- viscosity 65 mPas

- ivory color

- working time approx. 3 minutes

- demold time 0,5 - 1,5 hrs

- shore hardness 72 D

- e-Modulus 1000 MPa

- impact resistance 26 kj / m2

Technical Bulletin

Download theTechnical bulletin for Formx Rhino [251 KB]

FormCast Rhino products

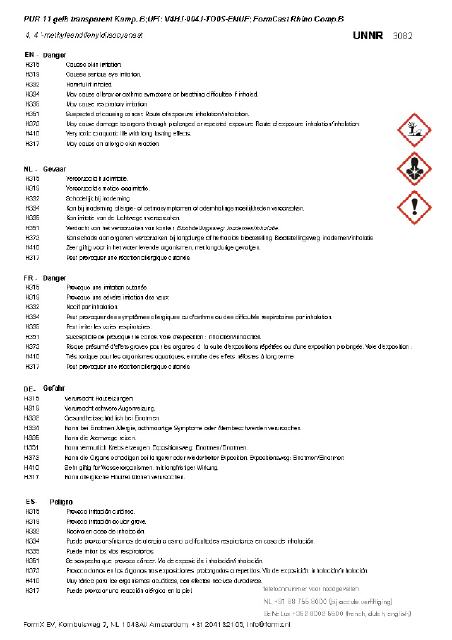

Safety Information

Rhino Slow

Safety Information Rhino Slow

FormCast Rhino resin testing

How to Use

Stir the individual components well before use. Weigh or measure both parts accurately and assemble in a clean and dry container and mix for 30 to 60 seconds. For the mixing cup, best use PP or PE plastic cups. Avoid contact with moisture as this will cause foam formation of the resin. When using Urefil filler, add these to the individual components and stir untill both have the same viscosity. Then let both of these components effortlessly blend together.

Guide

Let us help you find your way.

The list below may help you find what you are looking for via an alternative path.